In your 3D design file, the inner and outer surfaces of the model are closed to form thin walls, where:

At least two surfaces are connected with other thin walls, which are called supporting thin walls, as shown in the following figure:

Only one face is connected with other thin walls, which is called unsupported thin wall, as shown in the following figure:

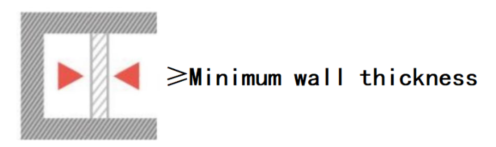

The thickness of thin wall is called wall thickness, which can be divided into supported wall thickness and unsupported wall thickness.

The wall thickness directly determines the strength of the printed article and also determines whether the model can be printed.

After the model is printed, it also needs to be processed by removing support, polishing, sandblasting, etc. These processes determine the minimum wall thickness of different materials. Only when the wall thickness reaches the minimum wall thickness requirement can the model be printed.

If there is a thin supporting thin wall area in your design, you need to adjust the wall thickness according to the size of the area, as follows (for example, if you choose 8000 resin material, the size of the thin wall area is within 5 * 5mm, and its minimum wall thickness is 0.6, the same for others):

| 材料 | 5*5mm | 10*10mm | 50*50mm | 100*100mm | 200*200mm |

|---|---|---|---|---|---|

| 8000 resin | 0.6mm | 0.8mm | 1mm | 1.2mm | 1.5mm |

| 8500 high toughness resin | 1mm | 1mm | 1.2mm | 1.5mm | 2mm |

| Transparent photosensitive resin | 0.3mm | 0.5mm | 1mm | 1mm | 1.2mm |

| White nylon | 0.8mm | 0.8mm | 1mm | 1mm | 1.2mm |

| Grey fiberglass | 0.8mm | 0.8mm | 1mm | 1mm | 1.2mm |

| Grey high toughness ABS resin | 0.8mm | 0.8mm | 1mm | 1mm | 1.2mm |

If you have unsupported thin-wall in your design, the minimum wall thickness requirements are as follows

| Material Science | 8000 resin | 8500 high toughness resin | Transparent photosensitive resin | White nylon | Grey fiberglass | Grey high toughness ABS | AlSi10Mg aluminum alloy |

|---|---|---|---|---|---|---|---|

| wall thickness | 1mm | 1mm | 1mm | 0.8mm | 0.8mm | 0.8mm | 1mm |